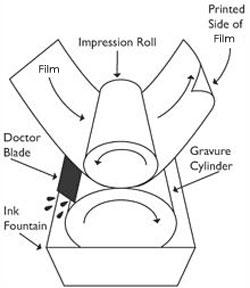

Roto Gravure Printing Process

Rotogravure printing has an important role in the packaging industry as it has many benefits. Rotogravure printing is a direct printing process, as the image that is engraved on the cylinder is directly engraved or printed to the substrate to provide proper ink lay down.

This increases the efficiency and look of the finished product because then we can easily achieve sharp image contrast with different depths on printing cylinder. The cost of cylinders is high initially, but they can be made economical by using the cylinders for long runs.

There are many more benefits of Rotogravure printing like:

|

- Rotogravure printing provides the fastest printing speed when compared to flexographic printing.

- The rotogravure printing also gives efficiency in high production with low wastage.

- It is more suitable for colors like human face and skin and provides a better image when compared to flexographic printing.

- The Rotogravure process is the best choice when you have to print millions of impressions, this process not only provides high quality but also color consistency.

- The rotogravure printing avoids the impression of the machine shade and also brilliantly brings uniformity of the color patterns to the images.

- With rotogravure printing we can actually get millions of prints of the images and this helps in reducing the overall costs, which is not so in the case of flexographic printing.

- The cost of the repeated printing is very low in rotogravure printing, as the printing plates are already prepared.

- The finished product that you get from the rotogravure printing is more attractive as it has many bright colors with high gloss and the images are clear as it has high color strength when compared to the flexographic printing because in rotogravure printing thick ink layers are used.

- Rotogravure printing provides photographic quality of the images, superior selection and use of colors, best appearance, and highest perceived value for your product with added attractiveness to the persons who see the product; this makes us wonder whether the flexographic printing can even match rotogravure printing.

- Rotogravure printing requires fewer variables to be controlled than flexographic printing processes, which helps to give more consistent and better print quality throughout the run.

- Not only this, it also provides consistent color throughout a press run even when you print a million copies.

- Rotogravure printing provides versatility in the process as it can print for the publication printing where thin paper or coated paper is used and also in the packaging printing where they use, plastic film, cardboard, aluminum foil, laminates etc and this versatility cannot be found in the flexographic printing